Advanced 2.5

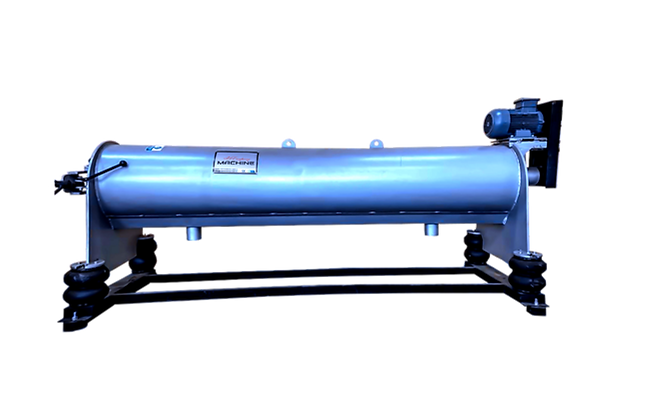

Trend 2.5 carpet wringing machine is manufactured with 1200 rpm spin cycle, 2.5 meters inner drum width and equipment that can reach a daily capacity of 1350 m².

2500 mm.Inner Drum Length

1200

Wring Out RPM,

1350 m2

Daily Capacity

Button

Control Panel

10+ Years High Performance

2

Year Warranty

Explore By Yourself

Technological Control System

Suspension System

The entire system is intentionally designed with an initial imbalance during the manufacturing process. Various vibrations may occur during the spinning of carpets due to factors such as fiber type, thickness, length, width, and more. Additionally, vibrations can be present when the machines are starting or stopping. To address this and provide a longer-lasting experience, an airbag (shock absorber) system has been incorporated. This suspension system is one of the crucial components that significantly impact the performance of the spinning machines. Our Advanced 2.5 machine is equipped with 4 suspensions for optimal functionality.

Cover System

Economic Advanced 2.5 has a manual cover system. The cover system, which is the most sensitive part of the wringing machines, provides performance experience without problem by increasing the lifetime of the machine if it is designed correctly. With the R&D and innovation studies we have done, the cover problem that may occur in the spinning machines has been minimized.

.png)

Electrical panel

Schneider brand control panel is used in our Advanced 2.5 carpet wringing machine. This makes our machines more resistant to electrical problems.

.jpg)

Movement System

Advanced 2.5 economical carpet spinning machine has a thermal control panel. In addition, electronic parts in the components are preffered to be with open to the long years use and will not make any problem.

Performance-Oriented Innovation

Spin-Cycle

By considering the direction of rotation, carpets are placed in the squeezing machine to effectively remove water by utilizing the optimal operating speed and centrifugal force. The Advanced 2.5 machine operates at a squeezing speed of 1200 RPM (revolutions per minute). On average, carpets subjected to squeezing at the appropriate speed retain around 10% moisture. It is crucial to determine the correct rotation speed that ensures both effective squeezing and does not strain the machine. This consideration is essential for the longevity of the working components.

_edited.jpg)

Engine

It provides high performance and efficiency with its 5.5 kW motor power.

Pragmatist Production Approach

Material Selection

Our engineers have meticulously designed cost-effective carpet wringing machines, taking into account various factors such as material specifications, thickness, and optimal weight. They have paid careful attention to considerations like working hours, rotation cycles, and the lubrication system when selecting materials for bearings and beds.

Throughout the design process, our engineers prioritize efficiency and durability, ensuring that the chosen materials are suitable for the specific requirements of the spinning machines. By carefully considering these factors, we aim to provide machines that deliver reliable performance and require minimal maintenance.

With a focus on quality and attention to detail, our economical carpet spinning machines are engineered to meet the needs of the industry while maintaining a cost-effective approach.Our machine is made of hot-dip galvanized material.

Dimension

Trend 2.5 has a length of 3250 mm, a width of 1100 mm and a height of 1300 mm.

_edited.jpg)

Inner Drum

In Advanced 2.5 , the inner drum diameter is 420 mm and the inner drum length is 2500 mm. The inner drum of our machine is made of Galvanized material.

World Class Services

Training

As AFC Machine, we care about getting maximum efficiency and quality from every machine we produce. Providing high performance is achieved with a use in accordance with machine processes. At this point, necessary information and trainings are given to the users for the machines we manufacture, and it is ensured that the machine is utilized at the highest capacity.

Shipping and Installation

The machines are loaded onto the shipping vehicle with protective materials against impacts. During the shipment, the products are carefully transported without any damage, and the shipped machines meet to the user in accordance with ready to use.

Warranty

Machines produced with high durability and quality materials are designed to be suitable for your long use. All models are guaranteed 3 year against the manufacturing defects .In addition, our machine, spare parts availability and advanced service equipment are guaranteed for 10 years.

Worldwide Maintenance Support

The machines produced by AFC Machine are exported to more than 50 countries around the world. We offer a worldwide support and expert service network against all possible problems.

Lifelong Partnership Program

As AFC Machine , we have been following an understanding of uninterrupted service for 15 years with the productions we have realized in the process since the day we were founded. We make it our principle to be with you in every matter you need, from machine production to the process after use.

Frequently Asked Questions

What is the purpose of a carpet wrining machine?

Carpet wringing machines play a vital role in the carpet washing process, serving as a crucial stage after the carpets are cleaned. The spinning process holds immense importance as it greatly reduces the drying time, leading to enhanced workflow efficiency.

Specifically, Speed carpet spinning machines are designed to effectively remove approximately 95% of the remaining water from the carpets after washing. This thorough water extraction contributes to a more comprehensive and efficient cleaning process.

What features do carpet spinning machines have?

A carpet squeezing machine possesses certain features to effectively remove excess moisture and water from the carpet, making it a high-quality machine for complete water extraction.

Carpet squeezing machines are designed to efficiently eliminate excess water from the carpet, thus preventing the formation of bacteria and microbes caused by moisture. This ensures that the washed carpets gain enhanced hygiene.

The carpet squeezing process minimizes the drying time of the carpet, contributing to increased productivity. By reducing time and space requirements, it helps achieve high customer satisfaction.

The machines are typically equipped with powerful squeezing capabilities, ensuring thorough water removal from the carpet. They may also incorporate features such as adjustable squeezing speeds, reliable bearing systems, and efficient water drainage mechanisms.

Overall, carpet squeezing machines are designed to optimize the drying process, enhance hygiene, and improve overall efficiency in carpet cleaning operations.

What sizes of carpets can be washed with a carpet spinning machiness?

The suitability of carpets for a carpet spinning machine is primarily determined by the machine's capacity. A standard carpet spinning machine is capable of accommodating carpets with widths ranging from 2 to 4 meters. However, for washing larger-sized carpets, industrial-sized carpet spinning machines are more suitable. It is crucial to consider the size of the carpets you intend to wash before purchasing a carpet spinning machine and choose a machine with a capacity that aligns with your specific needs.